CASE LOADING AND PICKING ROBOT CELLS

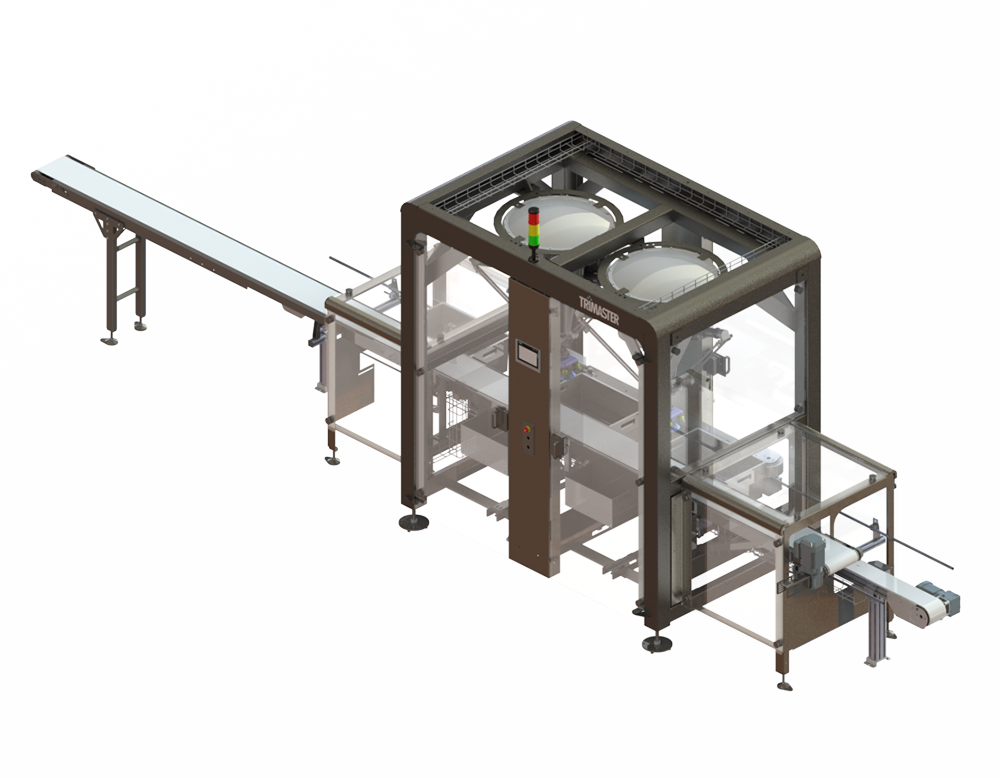

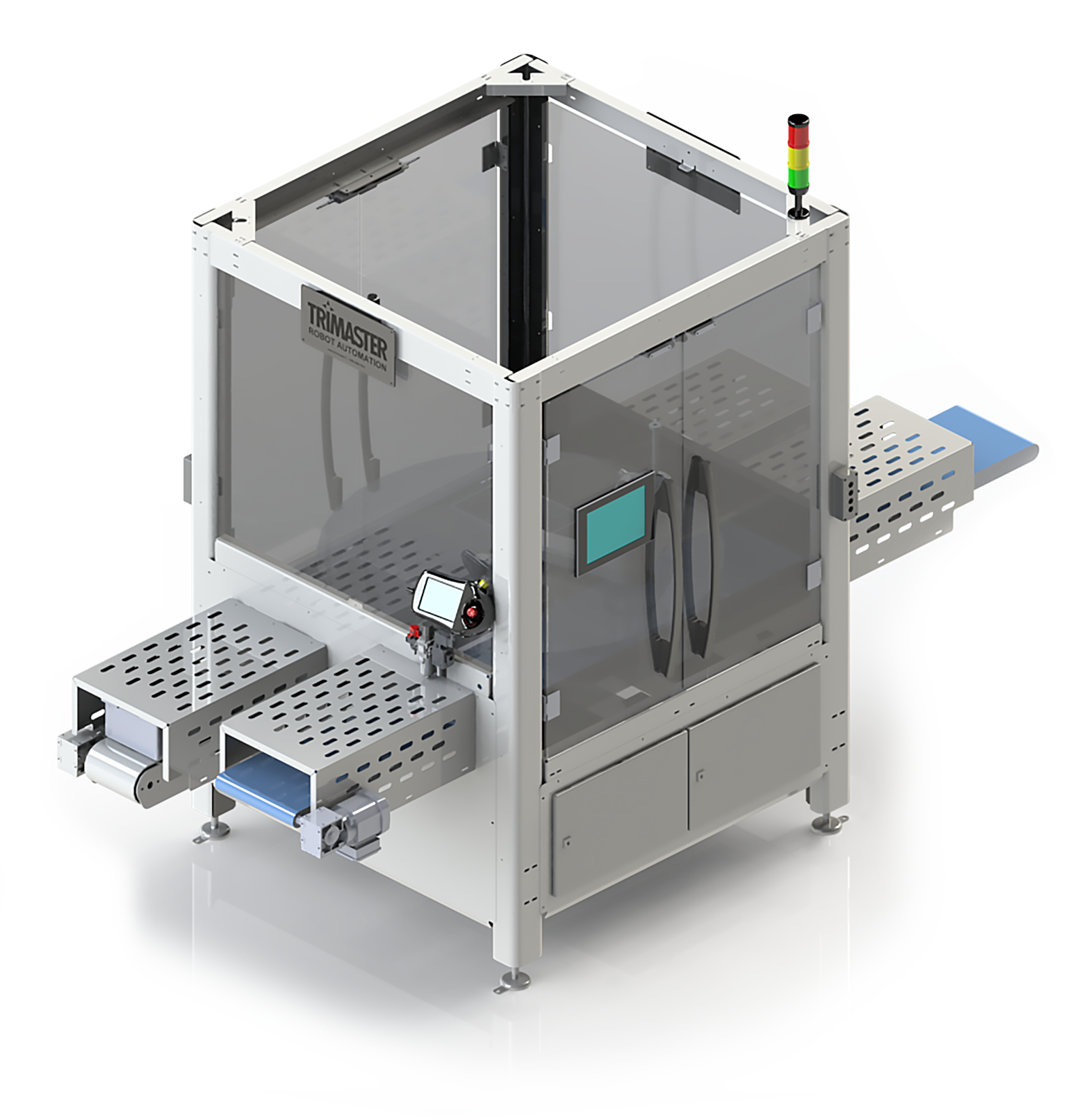

Box loding cell with one Flexpicker robot

Suitable for picking the product for one or two pieces per cycle. The products can be loaded either to a moving or stationary plastic or cardboard box. Can be equipped with machine vision camera and Pickmaster software. An easy-to-use operating panel interface. Product recipes and maintenance drives can be easily found.

Box loding cell with two Flexpicker robot

Suitable for picking the product for one or two pieces per cycle for high capasity. The products can be loaded either to a moving or stationary plastic or cardboard box. Can be equipped with machine vision camera and Pickmaster software. An easy-to-use operating panel interface. Product recipes and maintenance drives can be easily found.

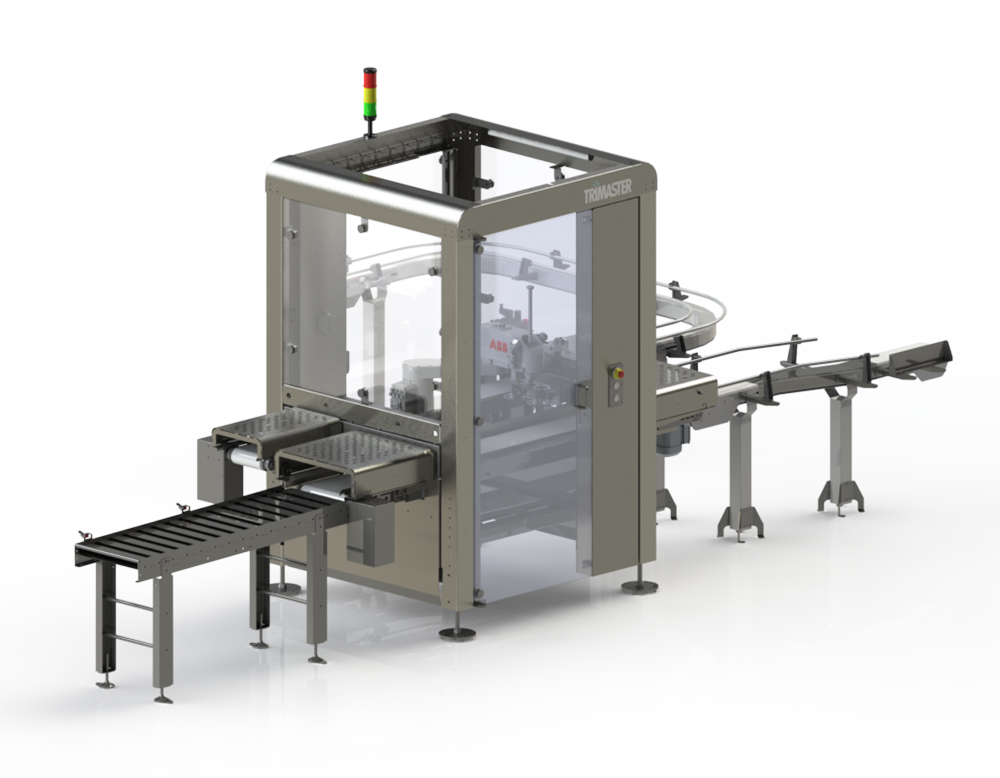

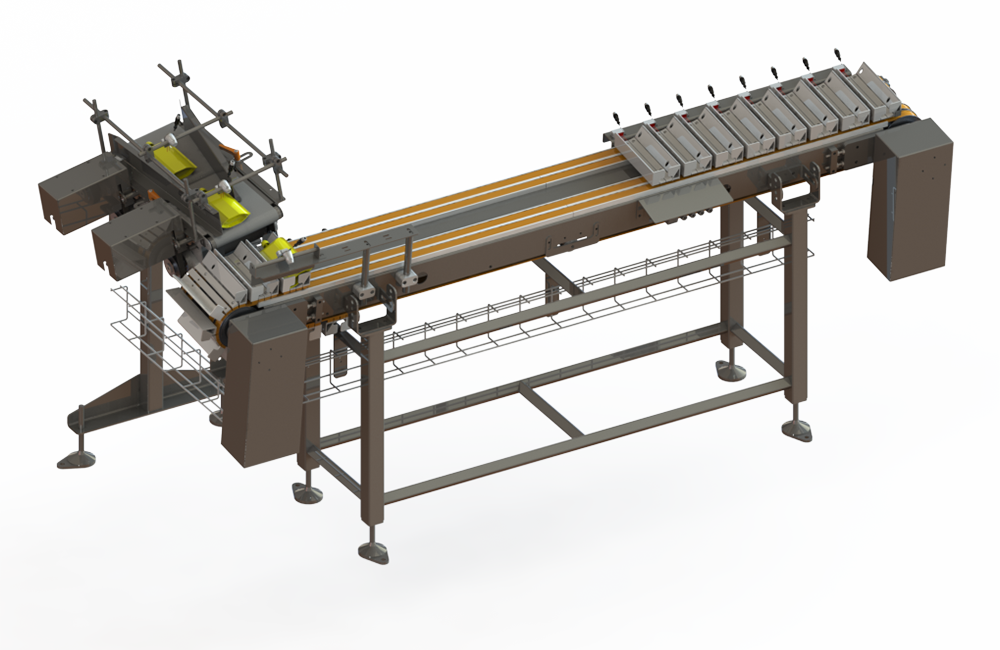

Cost-effective boxing cell with one Scara robot

Suitable for picking the product for a slightly lower capacity. The products can be loaded either to a moving or stationary plastic or cardboard box. Can be equipped with machine vision camera and Pickmaster software. An easy-to-use operating panel interface. Product recipes and maintenance drives can be easily found.

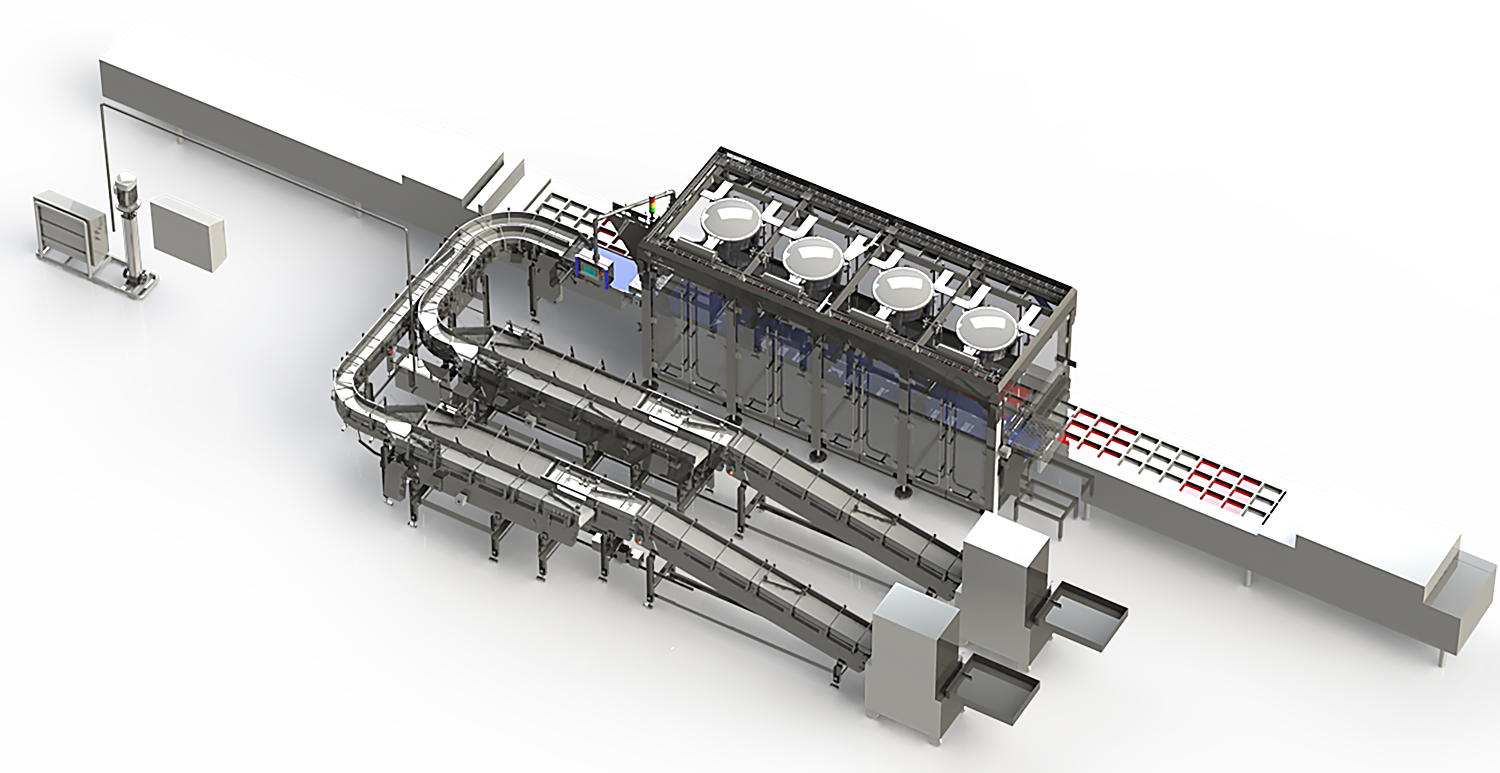

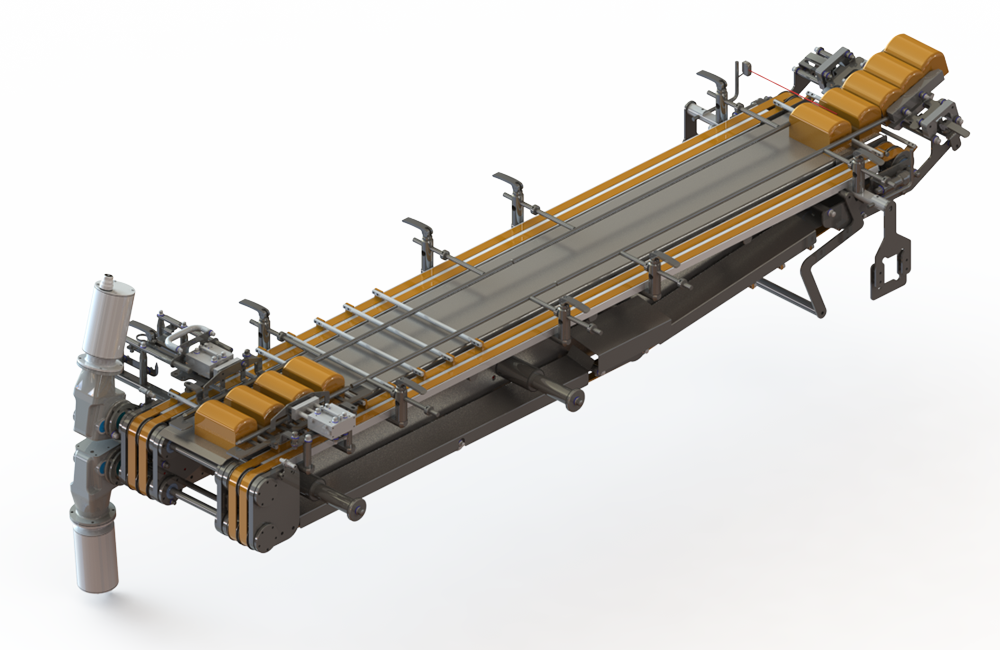

PACKING MACHINE LOADERS

Max. 6 picking robots

Products position and orientation can be recognized with vision system. Robots picks the products from the and move to the packaging machine.

Packing machines can be used as thermo forming machines, where products are transferred to the packaging machine cup or flowbag machines, in which case the products are transferred to the infeed conveyor of the packaging machine.

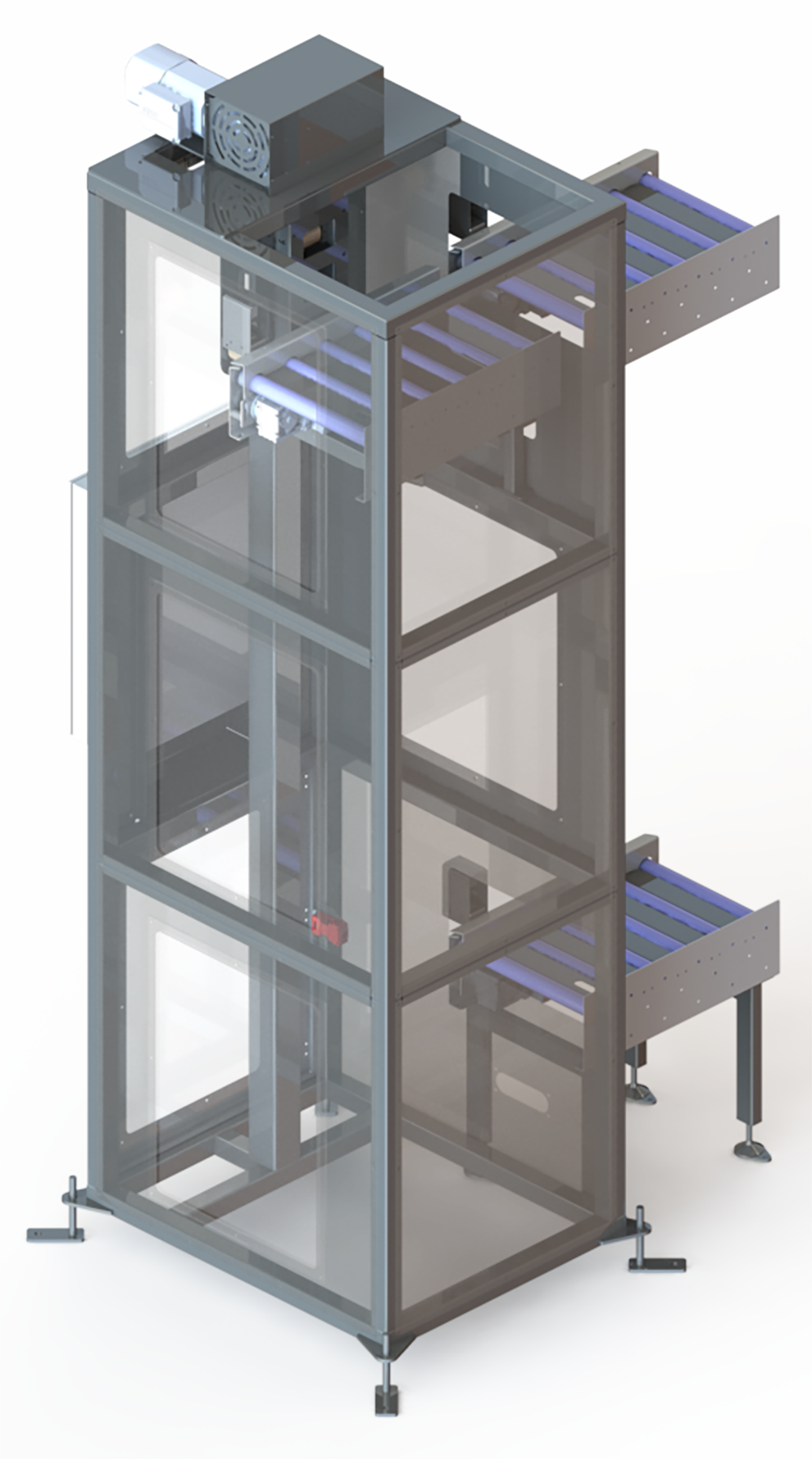

ROBOTCELL PERIPHERALS

Case loading cells can be equipped with a wide range of peripherals. Typical side chargers are barcode scanners, box direction detection device, turntables, box stacker, lifts, etc.

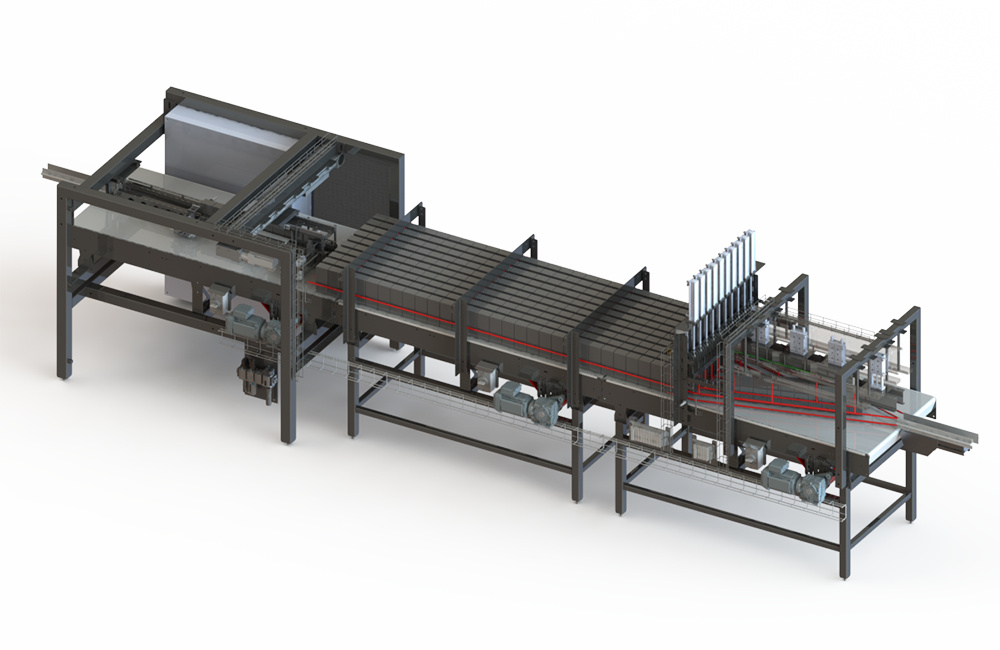

GROUPING DEVICES

BOX LOADING ROBOT RANGE

IRB-1200 / IRB-360 / IRB-920T